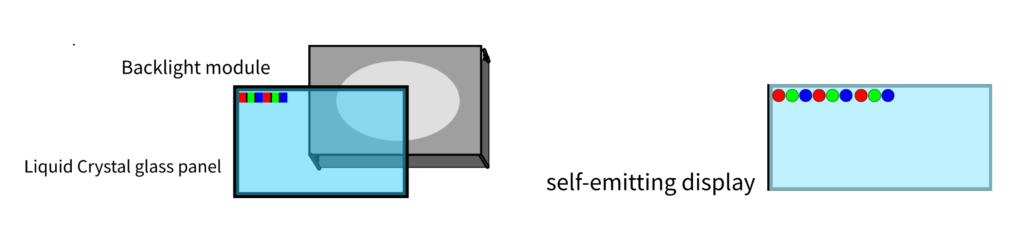

OLED displays have been gaining a lot of attention in recent years. OLED, short for organic light-emitting diode, is a significant departure from LCDs. LCDs use liquid crystals like shutters and require a backlight that is always on to display images. Even when the image is very dark, some backlight still comes through, which limits the contrast ratio of LCDs. On the other hand, OLEDs are self-light-emitting devices, and each pixel can be turned off if needed. There are no backlights, so the contrast for OLED panels is superb, with the darkest level being pure black. You can easily see the difference when showing a picture of the night sky.

Despite all of these excellent performances of OLED, there are still some challenges when it comes to mass production. Since the materials used in OLED displays are organic, they are very unstable when exposed to oxygen and water. The process to distribute OLED on the base panel and seal it to prevent exposure to oxygen and water is much more challenging than with LCDs. Another disadvantage is OLED displays can have a shorter lifespan than traditional LCD displays, particularly when it comes to blue pixels. This is because blue OLEDs tend to degrade more quickly than red or green OLEDs, which can lead to color shifting and reduced brightness over time.

Tech Cruiser’s Insight:

Korean panel makers have been leading the way in OLED display manufacturing, investing years of research and development into this field. LG Display has established a dominant position in producing large-size OLED displays for TVs, while Samsung has gained a stronghold in manufacturing small-size OLED displays. Despite the significant progress made in the vaporization process, the challenge of achieving mass production using this method remains. As a result, researchers are exploring alternative methods, such as printing processes, although they are not yet ready for mass production.

Recently, a new concept of display has been emerging: micro LED displays. Unlike OLED, micro LED is not organic; it is essentially just a lot smaller version of LEDs. With the use of tiny, self-emitting LEDs, micro LED displays can achieve high contrast ratios like OLED, but with even higher brightness levels. Micro LED is like traditional LED, it doesn’t degrade easily like OLEDs. , making them a promising technology for future displays.

The most challenging part of micro LED display is how to make these tiny LEDs line up on the base where the control circuits are. Since every pixel needs 3 micro LEDs (red, green, and blue), it is calulated that a very common 55″ FHD TV will need almost 4 million (1280x1024x3) LEDs. Aligning millions of tiny LEDs in the right position is a daunting task, especially considering that each pixel requires three micro LEDs (red, green, and blue) to achieve high-quality color reproduction. Despite the challenges, advancements in micro LED technology continue to pave the way for future displays with higher contrast ratios and brighter images.

During the Touch Taiwan Exhibition 2023, AU Optronics (AUO) showcased their micro LED manufacturing process and ecosystem. One of the critical steps highlighted in the demonstration was mass transfer micro LED chips from the wafer to the display panel. This process is crucial to ensure that each LED is correctly positioned and functioning as intended, which is a significant challenge in the mass production of micro LED displays.

Explore our earlier article on the Touch Taiwan Exhibition, featuring some micro LED products.

https://thetechcruisers.com/3-things-to-see-at-touch-taiwan-a-review-of-futuristic-displays/

As technology continues to evolve, we can expect more advancements in the display industry, and it’s fascinating to see how new technologies will continue to shape the way we interact with modern devices.