Step into the world of Artificial Intelligence, the pinnacle of cutting-edge technology. AI isn’t just shaping our future, it’s redesigning our future in all sorts of exciting ways. From data centers to cars to consumer electronics, AI is making everything faster, smarter, and more efficient. But what’s really cool is that AI is still in its early stages of development, which means there are endless possibilities for the future.

In this post, we’re going to focus on what Taiwanese high-tech companies are doing best: the hardware side of AI computing. These companies are at the forefront of developing the cutting-edge chips and systems that power AI applications.

First, let’s dive into the heart of AI hardware: processors. NVIDIA currently leads the pack in the realm of AI processors, with TSMC playing a pivotal role in this journey. The importance doesn’t just lie in manufacturing the processor chip using cutting-edge semiconductor technology; it’s also in how the chip is packaged for integration into AI systems.

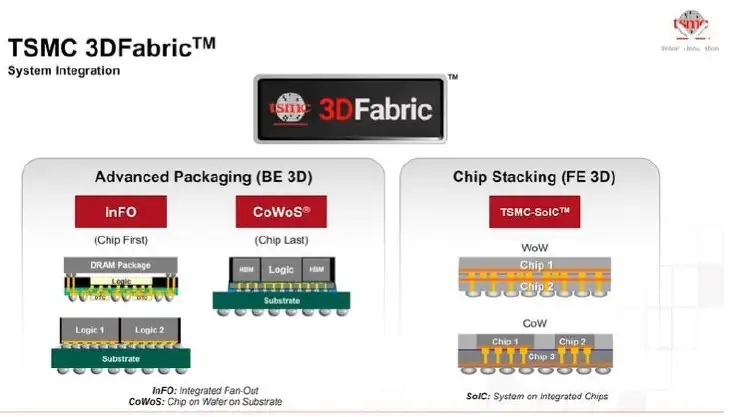

TSMC(2330.TWSE, TSM.NYSE), a dedicated semiconductor foundry since its establishment in 1987, stands apart from Intel by not engaging in self-branded IC design. Instead, its sole focus is on semiconductor manufacturing processes. Today, it possesses the world’s most advanced IC foundry process technology. Achieving high performance isn’t just about the foundry process; the packaging process is equally crucial. TSMC has devoted itself to advanced packaging, known as TSMC 3DFabric(TM). This innovative packaging technology has significantly boosted performance by stacking memory chips on logic wafers, reducing the distance high-speed signals need to travel. Additionally, deep trench capacitor wafers can be stacked with logic wafers, further enhancing system performance.

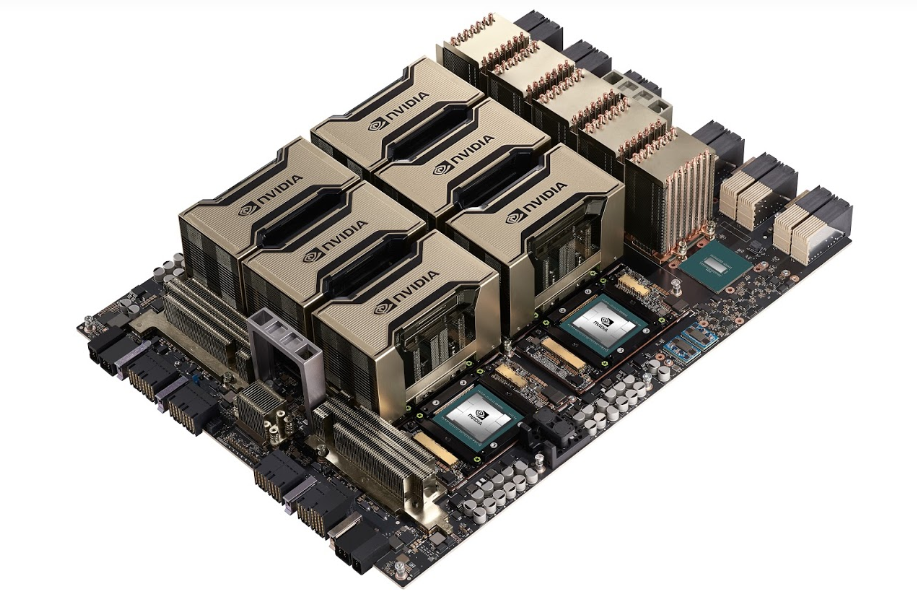

Next, let’s delve into the system assembly process. Once the processors are fabricated, they are mounted onto the PCB board as modules. By assembling multiple modules together, a GPU baseboard takes shape. Similar to the assembly of a personal computer, a motherboard comes into play, housing the main CPU. The fusion of the baseboard and motherboard creates a server. These assembly processes involve hundreds and even thousands of components. The manufacturing process not only demands meticulous production but also requires effective supply chain management.

Taiwanese companies such as Wistron (3231.TW) and Quanta (2382.TW) boast over two decades of experience in the computer manufacturing industry. Wistron, known for its contributions as an iPhone supplier, and Quanta, a major NB ODM (Notebook Original Design Manufacturer) with esteemed customers like HP and Dell, have been at the forefront of this intricate assembly artistry.

Tech Cruiser’s Insight:

Wistron has been a longtime partner with nVIDIA.As market information has revealed, nVIDIA’s DGX server series may be exclusively supplied by Wistron.

The AI industry is experiencing an unprecedented boom, and we’re merely scratching the surface of this AI era. Every player in the field is diligently working on strategies to make their mark in this burgeoning landscape. Taiwan’s high-tech companies, reminiscent of their pivotal role in the early days of personal computing, continue to hold a crucial position within the AI industry. They are the architects of AI’s foundation, constructing AI hardware to shape the future. To truly grasp the trajectory of AI development, one must delve into this critical realm. The journey has just begun, and the possibilities are limitless.